巨头之战:重新外包与友谊外包

AI智能总结

AI智能总结

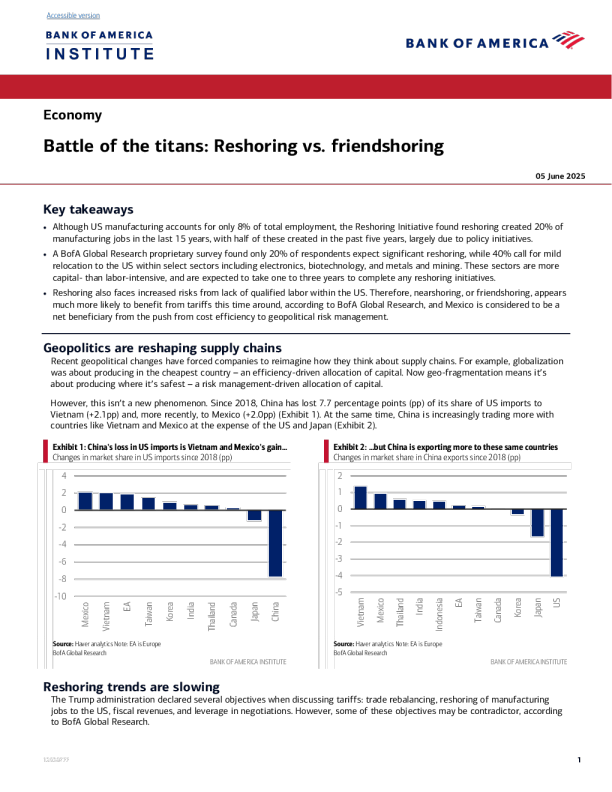

Battle of the titans: Reshoring vs. friendshoring 05 June 2025 Key takeaways •Although US manufacturing accounts for only 8% of total employment, the Reshoring Initiative found reshoring created 20% ofmanufacturing jobs in the last 15 years, with half of these created in the past five years, largely due to policy initiatives. •A BofA Global Research proprietary survey found only 20% of respondents expect significant reshoring, while 40% call for mildrelocation to the US within select sectors including electronics, biotechnology, and metals and mining. These sectors are morecapital- than labor-intensive, and are expected to take one to three years to complete any reshoring initiatives. •Reshoring also faces increased risks from lack of qualified labor within the US. Therefore, nearshoring, or friendshoring, appearsmuch more likely to benefit from tariffs this time around, according to BofA Global Research, and Mexico is considered to be anet beneficiary from the push from cost efficiency to geopolitical risk management. Geopolitics are reshaping supply chainsRecent geopolitical changes have forced companies to reimagine how they think about supply chains. For example, globalization was about producing in the cheapest country–an efficiency-driven allocation of capital. Now geo-fragmentation means it’sabout producing where it’s safest–a risk management-driven allocation of capital. However, this isn’t a new phenomenon. Since 2018, China has lost 7.7 percentage points (pp) of its share of US imports toVietnam (+2.1pp) and, more recently, to Mexico (+2.0pp) (Exhibit 1). At the same time, China is increasingly trading more withcountries like Vietnam and Mexico at the expense of the US and Japan (Exhibit 2). Reshoring trends are slowingThe Trump administration declared several objectives when discussing tariffs: trade rebalancing, reshoring of manufacturing jobs to the US, fiscal revenues, and leverage in negotiations. However, some of these objectives may be contradictor, accordingto BofA Global Research. But one bright spot in reshoring is job creation. In fact, reshoring and foreign direct investment (FDI) have created about twomillion jobs (around 20% of total manufacturing employment) in the last 15 years, according to the Reshoring Initiative.However, close to half of these jobs were created in the last five years. And job creation from initiatives like the Inflation Reduction Act (IRA) and the Creating Helpful Incentives to ProduceSemiconductors (CHIPs) Act may be losing steam. While these government projects contributed to the increase in the onshoringtrend between 2020 and 2022, those numbers have slowed over the past two years, after a peak of 350k jobs created (Exhibit3). Electrical equipment, appliances and components (mostly EV batteries), computers and electronics, as well as transportationequipment, led the pack with 75% of job creation over the last few years. Exhibit3: Reshoring related job gains peaked in 2022Reshoring and FDI job announcements (yearly, actual (inthousands)) Exhibit4: The US is a services-driven economyReal GDP, consumption, and real value added in services and goods sectors (actual, $ trillions) Putting reshoring into contextAdditionally, over the last several decades, the US has further transformed itself into a services economy, with services GDP growth consistently outpacing goods-producing sectors (Exhibit 4). Despite the relocation of supply chains into the US,manufacturing employment as a proportion of the total has been moving lower, currently only 8%, down from 30% in the 1980s. However, this isn’t necessarily bad news. Automation and offshoring of labor-intensive activities into low-wage countries havecreated a more efficient allocation of resources for the US as well as the rest of the world, according to BofA Global Research. Inother words, manufacturing careers have been largely replaced with higher-paying services jobs in the US over the past severaldecades. Reshoring is more prominent in specific sectorsTariffs affect various sectors differently, and a firm’s decisions to relocate supply chains or pass tariff costs on to final prices can have significantly different implications based on its industry. According to BofA Global Research, autos have been moreimpacted than branded pharma, while semiconductors were spared, etc. Moreover, even within sectors, there have been different reactions to tariff increases between large, small and medium-sizedcompanies due to differing abilities to front-run imports, smooth price increases, and preserve market share (read more on thisin theApril Small Business Checkpoint). Additionally, capital-intensive industries and some national security-related sectors are more likely to reshore more quickly thanlabor-intensive ones, where costs are much higher in the US, according to a recent BofA Global Research survey (Exhibit 5).Metals and mining, electronic manufacturing services, biotechnology and pharma (included